Mark Rowel Napulan, Ramir Lee, Zeigler Bros.

The Zeigler team toured three major shrimp producing countries in Asia to support its customers with practical solutions and technical approaches to controlling Enterocytozoon hepatopenai (EHP). EHP is an established microsporidian disease that causes slow growth in shrimp which continues to devastate Asian shrimp industries with US$ billion losses annually.

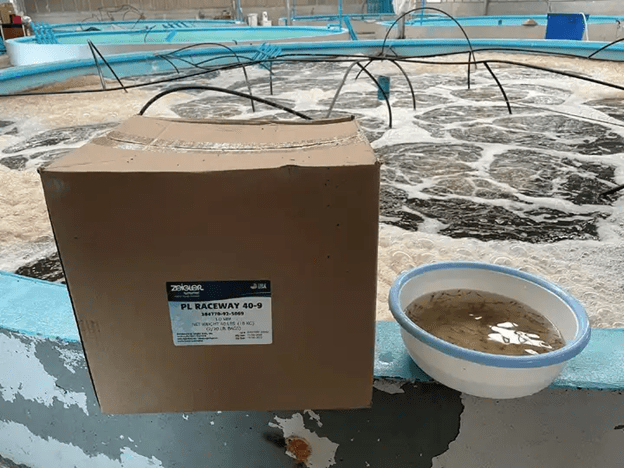

As a component of Zeigler’s customer support program, a series of technical seminars were hosted and presented in Phan Rang (Vietnam) and Kakinada and Nellore (India). The seminars were attended by a combined total of 229 shrimp hatchery owners, managers, technicians, consultants, and nursery farmers. In Thailand, the team visited nursery farmers to identify areas for improvement, and share techniques and experiences in shrimp nurseries. The team shared insights into its Precision Feeding Program (PFP) software. Zeigler developed the program to support PL Raceway 40-9 and PL Raceway Plus customers, providing an accurate feeding guide based on the carrying capacity of the system and the particular genetics of the animals. The most important feature of the program is its flexibility, enabling the manager to adjust and control feeding rates throughout the cycle. Properly managed, biosecure nursery systems have been successfully deployed as one part of the solution to prevent EHP.

Effective control of EHP depends on understanding and adapting management protocols based on scientific data on the biological characteristics of the pathogen, its modes of infection and the effectiveness of methods of control. EHP is a microsporidian pathogen that produces spores that can remain dormant for up to two years. Once the environmental conditions become favorable, the spores start to activate and infect shrimp through polar tube extrusion. It is very important to note that EHP spores are described as being clusters of

Seminar in Phan Rang, Vietnam attended by major PL suppliers.

elliptical to somewhat ovoid spores (1.1 ± 0.2 by 0.6-0.7 ± 0.1 microns) through H&E stained hepatopancreas samples. Because of their small size, spores are difficult to observe under the microscope, requiring skilled, experienced microbiologists to find at 100x objective using oil immersion. The small size can bypass some commonly used filtration systems in the hatchery.

PL Raceway 40-9 supporting high growth and survival rates in a nursery system in Thailand.

Due to the complexities of the diagnosis of EHP through microscopy, properly applied PCR techniques must be used throughout the production process to identify and eliminate the pathogen. When correctly applied, PCR testing is very sensitive. Nevertheless, efficiently identifying sources of infection depends upon the effectiveness of sampling. The number of samples needed to detect infection increases depending on the prevalence of the pathogen. Thus, the effectiveness of PCR diagnostic strategies for screening potential sources of infection must be carefully evaluated.

Recent studies on cohabitation suggest that spores can be transferred orally through ingestion of feces and cannibalism. Spore densities are concentrated in filterfeeding animals like mussels, oysters and polychaetes and can be ingested through sediments suspended in the water column. Hence, the approach to prevention of EHP must be holistic, starting from the maturation systems in the hatchery to the harvest and post-harvest pond treatments in the farm.

Management of EHP in the hatchery

EHP can enter maturation systems with infected broodstock, through the water, or in live or fresh feeds carrying viable EHP spores. Beginning with certified SPF broodstock is the first step in prevention. Being filter feeders, live polychaetes in particular have been shown to be significant potential carriers of EHP. It is highly recommended to use only SPF live polychaetes in maturation systems. If using alternative diets, such as squid and other fresh feeds like mussels, these must be subjected to -20°C, freezing for more than 48 hours to inactivate the spores prior to feeding. In this regard, we highly recommend the use of our Redi-Mate maturation feed to start the conditioning stage and through active spawning. Redi-Mate is an inert, manufactured biosecure maturation diet that has been shown to adequately replace up to 50% of live polychaetes in commercial trials and up to 60% of fresh feeds (without live polychaetes).

Reducing reliance on expensive and often limited supplies of live polychaetes past certain limits can result in decreases in spawn size and nauplii production rates. In the Western Hemisphere, live polychaetes are not used, maturation systems are larger, and broodstock costs are controlled by the use of local breeding programs and multiplication systems. Applying this model in Asia will require more investment in biosecure broodstock multiplication centers stocking PPL (parent post larvae) to reduce logistical costs and bottlenecks, and assure adequate supplies of genetically improved SPF breeders.

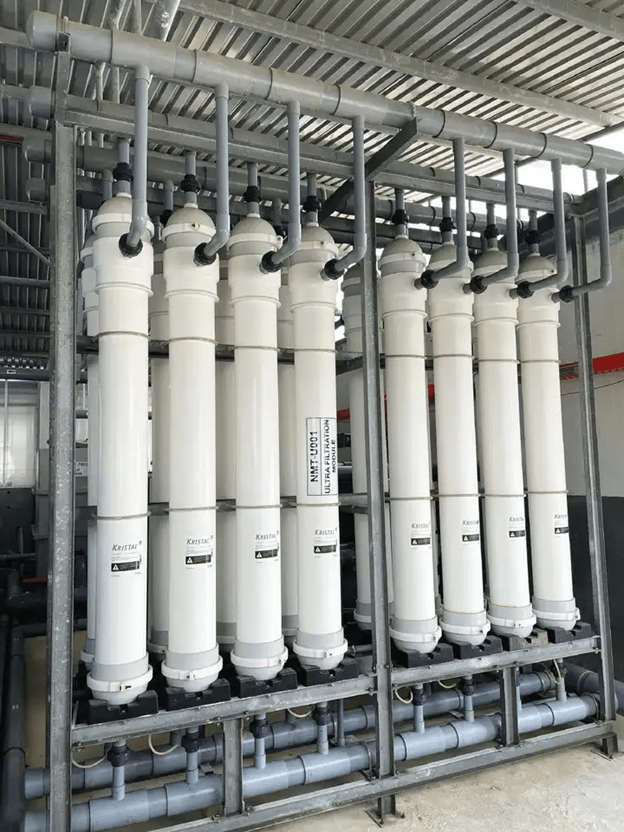

We also recommend incorporating ultra-filtration systems for water in the hatchery with 0.1 micron lower filtration to exclude spores. Research has shown that EHP spores can be inhibited with various treatment methods. Thus, treatment of all incoming water in the hatchery with either 40ppm of 65% active chlorine or 15ppm KMnO4 inactivates spores. Filling tanks with steam water and rinsing equipment with water at a temperature of 75°C for up to 1 minute could also help to inactivate spores.

The adoption of ultra-filtration systems is becoming a trend in Vietnam.

Additionally, hatchery technicians should select high-quality hatchery feeds formulated to optimize nutrition incorporating highly digestible ingredients. Zeigler recently launched its Z Pro diet in Asia, specially designed for shrimp post larvae (PL). This novel and advanced product was developed over the course of three years of continuous R&D at the Zeigler Aquaculture Research Center in Florida. It is gaining popularity and market share in many regions, and has been proven to reduce the usage of flake and dry feeds in some current commercial protocols by up to 40%. Improving feed utilization efficiencies in the hatchery tank reduces waste and improves water quality, lowering ammonia and Vibrio levels. The resulting more robust, stronger PL with improved survival are better able to resist pathogens like EHP in hatcheries, nurseries, and grow-out systems.

Management scenarios in ponds

Managing EHP in ponds is very challenging due to the much larger water volumes and culture areas that need to be treated. In areas with active EHP infections, water must be filtered or treated with the correct dose of the appropriate, approved product to inactivate spores. Also, consider that EHP spores are typically embedded in the pond bottom sediments, which can reduce the efficacy of chemical treatments. The use of well points and lined ponds that can be appropriately disinfected can improve the outlook for successful crops in areas with ongoing EHP outbreaks.

Moreover, stressors can trigger EHP infections in shrimp ponds. Nursed PL can produce more robust and faster-growing animals due to compensatory growth. A properly designed and managed nursery phase reduces the overall culture period and the exposure of the shrimp to pathogens and stressors. As in the hatchery, similar water treatment procedures and physical exclusion with the use of ultra-filtration (0.1 microns) should be adopted. Efficiently feeding high-quality nursery feeds will help improve feed conversion and thereby reduce organic waste in the system. Controlling the feed conversion ratio (FCR) in the nursery is critical to reducing stress resulting from overfeeding and the subsequent deterioration of nursery and pond water quality.

Performance data from 17 separate trials conducted in Asia for Zeigler’s PL Raceway 40-9 product demonstrate survival rates averaging 92.4 ± 6.1% achieved, with FCR values of 0.87 ± 0.0. These trials clearly demonstrate that this nursery diet is cost-effective and improves animal health while reducing ammonia and nitrite inputs into the system.

Ponds with sandy loam soil and high sedimentation should be lined with high-density polyethylene plastic (HDPE).

For ponds known to be previously infected with EHP, farmers should treat them with the proper lime product. It is very important to know your lime and pay attention to its solubility in water. Burnt lime (calcium and magnesium oxides, CaO and MgO) and hydrated lime [Ca(OH)2] can increase pH to levels up to 12 or higher and eliminate EHP spores at a dose of 6 mt/ha. A simple way to test a liming product is to put it in water and observe whether it will raise the temperature to 50°C. The product must be sieved through a 100mesh net. It should be noted that for this hot lime to react, the soil must be moistened. The liming should cover the entire pond bottom to optimize its treatment impact.

Recently, researchers found that EHP-infected shrimp exhibit white feces when co-infection with Vibrios occurs. In this case, farmers should pay attention to controlling Vibrios throughout the entire shrimp culture

cycle. We strongly recommend selecting probiotics proven effective in the hatchery and in pond grow-out, properly demonstrated to colonize the shrimp gut and inhibit growth of Vibrios in the water.

In an effort to control EHP, farmers must demand healthy, EHP-negative PL from their hatcheries. These test results must be from a robust ongoing sampling program carried out by a properly accredited and independent laboratory certified by the government. Zeigler is committed to helping hatcheries maintain and enhance PL survival, growth and health to meet the increased scrutiny and higher PL quality necessary to maintain profitability in EHP-affected areas.

Perspectives

While the shrimp farming industry continues to face hurdles and challenges to increase production due to the impact of EHP, Zeigler will continue to improve its products and technical support by strengthening R&D efforts, improving manufacturing processes, and reaching out to its clients. Finally, we recognize the role of various research institutions and the importance of collaborative work efforts to find real-world solutions to support the needs of our customers worldwide.

More information:

Mark Rowel Napulan

Email: mark.napulan@zeiglerfeed.com

Asia Sales Manager Zeigler Bros., Inc.

Ramir Lee

Regional Technical Manager, Asia Zeigler Bros., Inc.