June 2023

By Mark Rowel Napulan, Peter Van Wyk, Ramir Lee, Chris Stock, Craig L. Browdy, Zeigler Bros.

Shrimp farming has grown in an unprecedented manner over the past three decades driven by growing populations and increasing demand for healthier protein sources. When growth in the supply of shrimp from capture fisheries stalled, shrimp farming presented a sustainable new supply to fulfill market demand. Today, more than half of the shrimp consumed globally is farmed, contributing to the economies of many countries. The industry has evolved from simple stocking of wild-caught post-larvae (PL) to a more organized and fully enclosed culture cycle. Over the years, the industry has benefited from improvements in genetics, advances in feed formulation, disease detection techniques and technological advancements in farming practices. All these improvements are interconnected and collectively help support a more stable global shrimp production.

Improved genetics has been one of the most impactful advances for shrimp farming, and faster growth has long been a priority for genetic programs. Genetic selection programs can yield an 8-10% improvement in shrimp growth rates per generation. These improvements in shrimp growth rates are manifested not only in the grow-out phase but also in larval shrimp. In many hatcheries, typical PL harvest weights have increased from 2.5-3.5 mg 15-20 years ago, to 4-5 mg today. As growth rates increase, the total demand for feed also expands to fulfill the higher nutritional requirements of the animals. Our experience suggests that the total feed input per PL produced has increased by 30-50% compared to 15-20 years ago. This increased nutritional demand of faster-growing larvae requires not only more feed but also higher quality feeds. Against this backdrop, PL prices have remained relatively flat while other production costs, such as labor and energy costs, have risen. As a result, many hatchery managers view feed as a cost to be minimized.

Effects of ammonia on growth

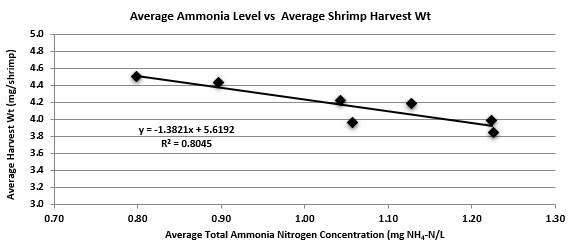

Trying to support the faster growth of the shrimp with cheap, low-quality feeds is not a sustainable strategy. Low-quality feeds are less efficiently converted into shrimp biomass, resulting in the buildup of organic wastes and ammonia in the culture system. Ammonia is toxic to shrimp larvae and adversely affects larval health, survival and growth. Research at the Zeigler Aquaculture Research Center (Z-ARC) has demonstrated that ammonia levels as low as 1 mg/L negatively impact PL harvest weight (Fig. 1).

Research at Z-ARC has focused on developing high quality larval diets that can maximize the growth potential of shrimp larvae while minimizing negative impacts on water quality. Our approach is to closely match the nutritional profile of the feed to the nutritional requirements of the shrimp and to utilize high quality ingredients with high digestibility. Building on 40 years of experience in larval shrimp nutrition, researchers at Z-ARC spent three years testing ingredients and formulations in a highly replicated larval rearing research system to identify the most digestible ingredients and optimize the nutritional profile of a new diet for mysis and postlarval shrimp stages. The result of this effort was Z-Pro.

Z Pro – A Paradigm Shift in Larval Feed Design

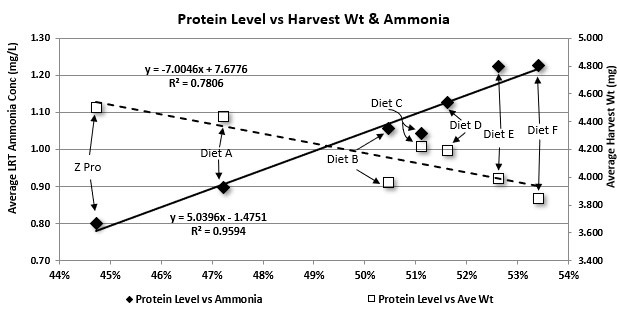

An important concept learned during the development of Z-Pro is that higher protein levels don’t always translate into better shrimp performance. Protein efficiency is also critical to feed performance. Protein efficiency is the grams of larvae produced per gram of protein fed. If the amino acid requirements of the larvae are met, a feed with a lower protein content but a higher protein efficiency will often outperform diets with higher protein levels. Many hatchery managers, while trying to provide the best diet for their shrimp at the lowest cost, select low-cost, high protein diets on the assumption that higher protein levels will support higher growth. This is not necessarily the case. Higher protein diets typically generate more ammonia than lower protein diets. Because of this, growth rates for diets with higher protein levels are often less than those with lower protein levels, especially diets formulated with optimal amino acid levels and made with highly digestible ingredients. This concept is clearly illustrated in Figure 2.

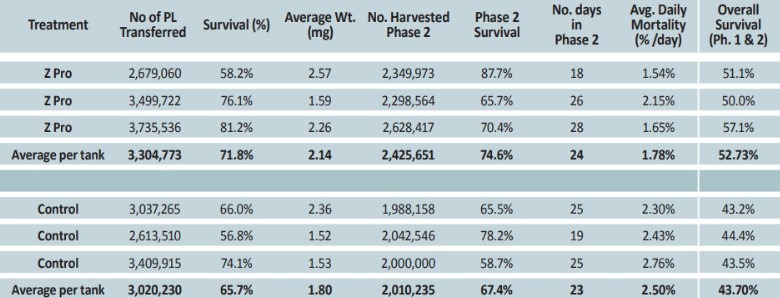

The benefits of feeding high-quality larval diets are not limited to the hatchery. Larger, robust postlarvae reared on quality feeds perform much better in subsequent production phases than smaller, weaker post-larvae reared on cheap feeds. In a study conducted at a commercial hatchery in Mexico, one group of larvae was fed Z Pro as the primary dry feed while a control group was fed the hatchery’s standard cocktail of competitor dry feeds. The two groups of PLs were then stocked in raceways at similar densities. Both sets of raceways were fed and managed the same, however, survivals in the raceways stocked with PLs that had been fed with Z Pro in the larval tanks were significantly higher than survivals in the raceways stocked with the PLs that had been fed the cocktail of dry diets in the larval rearing tanks (Table 1). Hatcheries that look at feed as an investment and focus on evaluating feed based on its conversion efficiency will realize the most benefits. It is important to recognize that cocktail protocols that mix high quality diets with low-quality feeds are diluting the full potential of top-performing products. Therefore, Zeigler recommends finding the best balance combination with Z Pro. In commercial hatchery trials, Zeigler technical staff have demonstrated that feeding Z Pro as a significant portion of a protocol can support a reduction in total feeding rates by as much as 43% compared to the control protocol with competitor diets. The reduction in feeding rates allowed by feeding a more digestible diet resulted in lower levels of ammonia and less water exchange, resulting in higher profits.

Impacts of survival on profit

Feeds that support higher survivals can improve the profitability of the hatchery even if these feeds are more expensive. A hatchery economic calculator developed by Zeigler, based on globally collected data, suggests that a 5% improvement in survival generates as much as a 17% increase in hatchery profits due to the increased revenues from PL sales. In the commercial hatchery trial mentioned above, the cost of the Zeigler diet was more than 50% higher than the cost of the cocktail feeds, yet the profit per tank was 9% higher.

Movie Forward

The use of faster growing genetic lines of shrimp is critical to the success of the shrimp industry. For the

industry to take full advantage of the genetic potential of the shrimp it is essential that hatcheries invest in quality feeds that support maximal growth while minimizing the negative effects of high ammonia levels. Quality hatchery feeds are a worthy investment whose gain is realized at both PL harvest and again on the farm. The more hatcheries that prioritize investment in high-quality hatchery feeds for the wellbeing of their crop, the greater the benefit will be for the whole industry. As shrimp price pressures increase production efficiencies must improve. Moreover, the most successful producers are those that focus on shrimp performance to achieve profitability, never sacrificing that performance while controlling costs. Only with this type of mindset can the industry continue to grow sustainably. This change will not occur overnight, but it must gather more momentum now in order to mitigate the risk of greater disease and to fully realize the potential of this industry.

This article was originally published in the Hatchery Feed and Management magazine June 2023 issue.